Everything You Need to Know About CNC Machining Service

CNC (Computer Numerical Control) machining service is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece. This technique enables high-precision production of parts with complex geometries, making it widely used in industries such as aerospace, automotive, and medical device manufacturing. By programming the machine with specific instructions, CNC machining ensures consistent, repeatable results, reducing human error and increasing efficiency.

CNC machining services offer numerous advantages over traditional manual machining, including enhanced accuracy, faster production times, and greater flexibility in handling various materials. The ability to produce intricate designs with tight tolerances makes CNC machining indispensable for companies that require high-performance components. As technology advances, CNC machining continues to evolve, integrating automation and AI-driven solutions to improve productivity and quality control.

How CNC Machining Service Works

CNC machining service begins with a digital design, typically created using CAD (Computer-Aided Design) software. The CAD model is then converted into a CAM (Computer-Aided Manufacturing) file, which contains instructions for the CNC machine. These instructions direct the movement of cutting tools, ensuring precise material removal based on the design specifications.

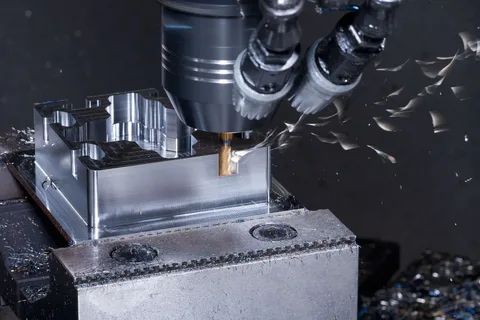

Once the program is uploaded to the CNC machine, the automated process begins, with the machine executing the programmed commands with minimal human intervention. The process can include milling, turning, drilling, and grinding, depending on the part’s design requirements. CNC machining offers superior precision, repeatability, and efficiency, making it the preferred method for producing high-quality components across various industries.

Types of CNC Machining Services

There are several types of CNC machining services available, each suited for specific applications. CNC milling is one of the most common services, involving rotating cutting tools that remove material from a stationary workpiece. This method is ideal for creating complex shapes and features, such as slots, holes, and contours.

CNC turning, on the other hand, involves rotating the workpiece while a cutting tool moves along it to remove material. This process is commonly used for cylindrical components like shafts and bushings. Other CNC machining services include laser cutting, electrical discharge machining (EDM), and waterjet cutting, each offering unique advantages for different materials and production needs. By selecting the appropriate CNC machining service, manufacturers can achieve optimal results in terms of quality, efficiency, and cost-effectiveness.

Benefits of Using CNC Machining Services

One of the primary benefits of CNC machining services is the ability to produce high-precision components with minimal error. Unlike manual machining, which relies on operator skill, CNC machining follows programmed instructions, ensuring consistent and accurate results. This level of precision is crucial for industries that require tight tolerances, such as aerospace and medical device manufacturing.

Another key advantage of CNC machining is its efficiency. Automated machining processes reduce production times, allowing manufacturers to meet tight deadlines without compromising quality. Additionally, CNC machining services can handle a wide range of materials, including metals, plastics, and composites, making them highly versatile for various applications. By leveraging CNC machining, businesses can improve productivity, reduce material waste, and enhance overall product quality.

Choosing the Right CNC Machining Service Provider

Selecting the right CNC machining service provider is essential for achieving the best results. When evaluating potential providers, consider factors such as experience, capabilities, and quality assurance measures. A reputable CNC machining service should have state-of-the-art equipment, skilled technicians, and a proven track record of delivering high-quality components.

Additionally, it is important to assess the provider’s ability to meet your specific requirements, including material compatibility, turnaround times, and cost considerations. Look for a company that offers comprehensive services, from prototyping to full-scale production, to ensure seamless project execution. By partnering with a reliable CNC machining service provider, businesses can streamline their manufacturing processes, reduce production costs, and achieve superior product performance.

Conclusion

CNC machining service is a vital manufacturing solution that offers precision, efficiency, and versatility. By leveraging advanced technology and automation, CNC machining ensures the production of high-quality components for a wide range of industries. Understanding how CNC machining works, the different types of services available, and the benefits it offers can help businesses make informed decisions when selecting a machining service provider. As technology continues to evolve, CNC machining will remain a cornerstone of modern manufacturing, driving innovation and efficiency in production processes.