3D Printing in Prototyping Faster, Cheaper, and More Efficient

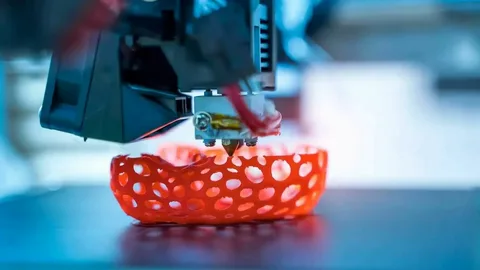

3D printing has revolutionized the way businesses and engineers create prototypes. Traditional prototyping methods often require complex machining, extensive labor, and significant financial investment. However, with the advent of 3D printing, the process has become significantly more accessible, cost-effective, and time-efficient. This innovative technology allows designers to rapidly transform digital concepts into tangible models, facilitating faster iteration and refinement.

The primary advantage of 3D printing in prototyping is its ability to produce highly detailed and accurate models in a fraction of the time required by conventional methods. Unlike CNC machining or injection molding, which may require specialized tooling, 3D printing directly constructs the prototype layer by layer from digital files. This eliminates material wastage, reduces production costs, and allows designers to test multiple variations quickly before committing to final production.

Speed: Accelerating the Prototyping Process

One of the biggest advantages of using 3D printing in prototyping is the drastic reduction in development time. Traditional manufacturing methods can take weeks or even months to produce a functional prototype due to the complexities of tooling, material preparation, and machining. In contrast, 3D printing enables businesses to produce a prototype within hours, significantly accelerating the product development cycle.

This rapid turnaround is particularly beneficial for industries that require quick iterations, such as automotive, aerospace, and medical device manufacturing. Engineers can test various design modifications in real time, making necessary adjustments before proceeding to mass production. The speed of 3D printing not only improves efficiency but also enhances innovation by encouraging experimentation without lengthy delays.

Cost-Effectiveness: Reducing Expenses in Prototyping

Cost reduction is another significant benefit of 3D printing in prototyping. Traditional prototyping processes often involve expensive materials and high labor costs associated with molding, casting, or machining. Additionally, the need for specialized tools or molds further adds to the overall expenses, making it financially impractical for small businesses or startups.

With 3D printing, the cost of prototyping is significantly reduced as it eliminates the need for costly molds and minimizes material waste. Most 3D printing technologies use only the exact amount of material needed to build the prototype, reducing excess costs. Moreover, businesses can afford to test multiple design iterations without incurring additional expenses, allowing for a more refined final product at a lower overall cost.

Efficiency: Simplifying the Prototyping Workflow

Efficiency in prototyping is crucial to ensuring a smooth transition from concept to final product. 3D printing simplifies the prototyping workflow by providing a seamless integration between digital design and physical fabrication. The ability to print complex geometries without additional assembly steps significantly reduces human intervention and potential errors.

Moreover, 3D printing allows for the creation of intricate structures that would be impossible or extremely difficult to achieve with traditional manufacturing techniques. This level of precision and design flexibility enhances the overall quality of the prototype, ensuring that any potential design flaws are identified and corrected early in the development process. As a result, businesses can optimize their manufacturing processes and improve overall productivity.

The Future of 3D Printing in Prototyping

The future of 3D printing in prototyping looks promising, with continuous advancements in materials, speed, and printing technologies. Innovations such as multi-material printing, metal 3D printing, and AI-driven design optimization are set to further enhance the capabilities of 3D printing, making it an even more valuable tool for industries worldwide.

As more companies adopt 3D printing for prototyping, we can expect a shift toward more sustainable production practices. The ability to print on-demand reduces material waste and energy consumption, contributing to a more environmentally friendly manufacturing process. With continued research and development, 3D printing will undoubtedly remain at the forefront of rapid prototyping, driving faster innovation and more efficient product development cycles.