Shrink Film Bundling Equipment: Key Benefits for the Packaging Industry

In today’s fast-paced packaging industry, efficiency and durability are crucial factors for businesses looking to optimize their operations. One of the most effective solutions for streamlining packaging is shrink film bundling equipment. This technology has revolutionized the way products are bundled, offering a cost-effective, secure, and visually appealing method of packaging. Whether for food, beverages, pharmaceuticals, or household goods, shrink bundling machines provide versatility and reliability.

This article explores the key benefits of shrink film bundling equipment, its impact on the packaging industry, and how integrating this technology can lead to improved productivity.

What is Shrink Film Bundling Equipment?

Shrink film bundling equipment is a type of packaging machinery designed to wrap products with a thin, heat-sensitive plastic film that shrinks when exposed to heat. The result is a tightly secured bundle that is easy to handle, transport, and store.

This equipment is commonly used across various industries, including:

-

Food & Beverage – Packaging bottled drinks, canned goods, and multipacks

-

Pharmaceuticals – Securing medical supplies and pill bottles

-

Retail & E-commerce – Bundling promotional items and multipacks

-

Manufacturing – Wrapping industrial parts and components

By automating the packaging process, businesses can significantly reduce labor costs while improving efficiency.

Key Benefits of Shrink Film Bundling Equipment

1. Cost-Effective Packaging Solution

Shrink bundling minimizes the need for excessive packaging materials like cardboard boxes, reducing overall costs. Additionally, it helps businesses save on storage and shipping expenses due to its space-efficient nature.

2. Strong and Durable Bundling

Unlike traditional packaging, shrink film provides a secure hold that prevents product movement during transportation. This reduces damage and ensures that products remain intact from the manufacturing plant to the retailer’s shelves.

3. Customizable for Various Product Sizes

Shrink film bundling equipment can be adjusted to accommodate different product shapes and sizes, making it highly versatile for businesses that package a wide range of items.

4. Improved Aesthetic Appeal

Products wrapped in shrink film have a sleek, polished look, making them more attractive to consumers. This is particularly important for retail environments where product presentation can influence purchasing decisions.

5. Environmental Benefits

Many shrink films used today are recyclable, helping businesses reduce their environmental footprint. Compared to traditional packaging, shrink film reduces waste and promotes sustainable packaging practices.

How Shrink Film Bundling Equipment Enhances Productivity

1. Reduced Labor Costs

Automating the packaging process reduces the need for manual labor, allowing businesses to allocate human resources more effectively.

2. Faster Packaging Speeds

Shrink bundling machines can handle high volumes of products per hour, increasing output without compromising quality.

3. Consistency in Packaging

With automated equipment, businesses ensure uniformity in packaging, maintaining a professional and standardized appearance for all products.

4. Space Optimization

Shrink-wrapped products take up less space compared to bulky packaging materials, optimizing warehouse and storage space.

Choosing the Right Shrink Film Bundling Equipment

When selecting the ideal shrink bundling machine for your business, consider the following factors:

-

Production Volume – Choose a machine that meets your packaging demands, whether small-scale or large-scale.

-

Film Compatibility – Ensure the machine works with different types of shrink films based on your packaging needs.

-

Automation Level – Decide between semi-automatic and fully automatic machines depending on your business requirements.

-

Maintenance Requirements – Look for equipment that is easy to clean and maintain for long-term operational efficiency.

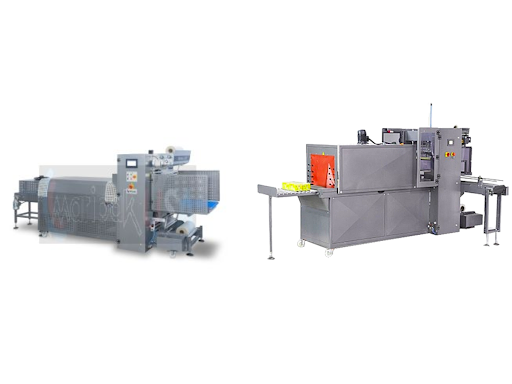

Integration with a Semi Automatic L Sealer Machine

To further enhance packaging efficiency, businesses often integrate shrink film bundling equipment with a semi automatic L sealer machine. This machine plays a critical role in preparing products for shrink wrapping by sealing the film around the product before heat is applied.

The benefits of using a semi-automatic L sealer machine include:

-

Increased Efficiency – Speeds up the sealing process, making it ideal for medium to high-volume packaging lines.

-

Precision Sealing – Ensures tight and secure seals, preventing film wastage.

-

Easy Operation – Requires minimal training, making it user-friendly for employees.

By combining both types of equipment, businesses can achieve seamless and efficient packaging operations.

Final Thoughts

Investing in shrink film bundling equipment is a game-changer for businesses looking to enhance packaging efficiency, reduce costs, and improve product security. By integrating additional tools like a semi automatic L sealer machine, companies can streamline their operations and increase productivity.