Spray Adhesives Market Companies Leading Growth: Outlook, CAGR, and Share

Spray Adhesives Market Size And Forecast by 2029

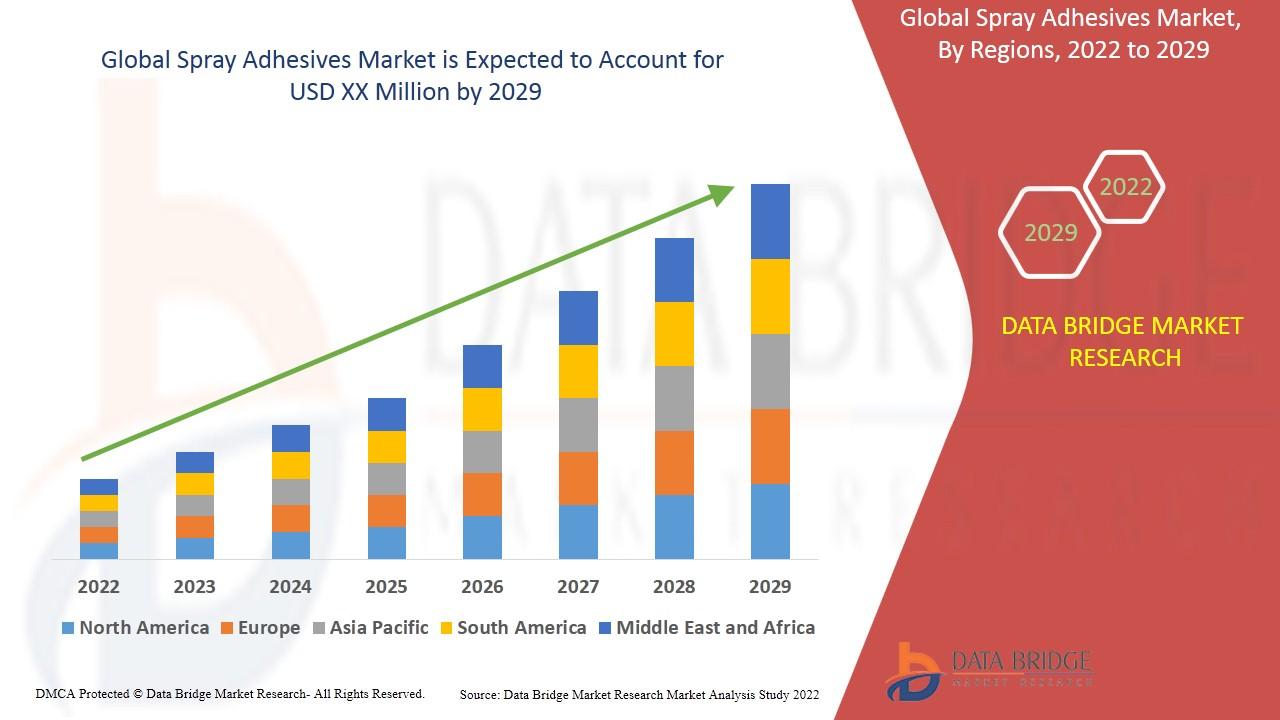

According to Data Bridge Market Research Data Bridge Market Research analyses that the spray adhesives market will witness a CAGR of 5.20% for the forecast period of 2022-2029.

Spray Adhesives Market is making waves in the industry with its latest advancements and market-driven strategies. As a leading player, Aerosol Glue Market continues to push boundaries by offering cutting-edge solutions that cater to evolving consumer demands. With a strong focus on innovation, Spray Adhesives Market has successfully expanded its global footprint, providing businesses with high-quality services and products. The rapid growth of Industrial Spray Adhesive Market is fueled by technological advancements, customer-centric approaches, and strategic partnerships. As Spray Adhesives Market strengthens its position, it remains committed to delivering value-driven solutions that enhance market efficiency and growth.

Contact Spray Adhesive Market's impact on the industry is undeniable, with continuous efforts to enhance product offerings and service quality. By leveraging data-driven insights and advanced technologies, Spray Adhesives Market ensures it stays ahead of market trends. The adaptability of Quick Bonding Spray Market has allowed it to address diverse industry challenges while maintaining a competitive edge. Companies relying on Spray Adhesives Market benefit from its expertise, robust infrastructure, and commitment to excellence. With increasing global demand, Multipurpose Spray Glue Market is poised for sustained growth, driving innovation and transformation across various sectors.

Our comprehensive Spray Adhesives Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-spray-adhesives-market

**Segments**

- **By Resin Type**: The global spray adhesives market can be segmented based on resin type into epoxy, polyurethane, rubber, acrylic, and others. Epoxy-based spray adhesives are known for their strong bonding capabilities and are extensively used in industries such as construction and automotive. Polyurethane spray adhesives offer flexibility and durability, making them suitable for applications where a tough bond is required. Rubber-based spray adhesives are commonly used for bonding rubber materials together, while acrylic-based adhesives provide fast curing and high performance.

- **By Substrate**: The market can also be segmented by substrate, including plastic, metal, wood, and others. Spray adhesives tailored for specific substrates ensure optimal adhesion and performance. Plastic substrates often require adhesives with strong bonding capabilities to overcome challenges such as low surface energy. Metal substrates demand adhesives that can withstand harsh conditions and temperature variations. Wood substrates, on the other hand, benefit from adhesives that offer both strength and flexibility.

- **By End-Use Industry**: The end-use industry segment categorizes the market based on applications such as packaging, automotive, construction, furniture, and others. Spray adhesives play a vital role in the packaging industry for sealing boxes, cartons, and bonding various materials together efficiently. In the automotive sector, these adhesives are used for interior components, headliners, and other assembly applications. The construction industry utilizes spray adhesives for insulation, flooring, and general bonding tasks. Furniture manufacturing relies on spray adhesives for efficient assembly and seamless finishes.

**Market Players**

- **Henkel AG & Co. KGaA**: A leading player in the global spray adhesives market, Henkel offers a wide range of products tailored for diverse applications. The company's innovative solutions cater to various industries, including automotive, electronics, and packaging, ensuring strong and durable bonds.

The global spray adhesives market is witnessing significant growth driven by the increasing demand from various industries such as construction, automotive, packaging, and furniture. The segmentation of the market based on resin type, substrate, and end-use industry provides a comprehensive overview of the diverse applications and requirements for spray adhesives. Each resin type offers unique properties and benefits, catering to specific needs in different sectors. Epoxy-based adhesives stand out for their strong bonding capabilities, making them ideal for demanding applications in construction and automotive industries. Polyurethane adhesives offer flexibility and durability, ensuring a tough bond in various scenarios. Rubber and acrylic-based adhesives serve specific purposes in bonding rubber materials and providing fast curing, respectively.

When considering the segmentation by substrate, the importance of tailoring adhesives to specific materials becomes evident. Plastic substrates require adhesives with strong bonding capabilities to overcome challenges such as low surface energy, while metal substrates need adhesives that can withstand harsh conditions and temperature variations. Wood substrates benefit from adhesives that offer strength and flexibility, addressing the unique characteristics of this material. By understanding the requirements of different substrates, market players can develop specialized solutions that ensure optimal adhesion and performance across various applications.

The end-use industry segment further highlights the versatility of spray adhesives and their critical role in different sectors. In the packaging industry, spray adhesives are essential for sealing boxes, cartons, and bonding various materials efficiently, enhancing the production process and product integrity. The automotive sector relies on these adhesives for interior components, headliners, and assembly applications, contributing to the overall durability and performance of vehicles. In the construction industry, spray adhesives are instrumental in insulation, flooring, and bonding tasks, offering efficiency and reliability in various applications. Furniture manufacturing also benefits from the use of spray adhesives for assembly and achieving seamless finishes, enhancing the quality and aesthetics of furniture products.

Market players like Henkel AG &Henkel AG & Co. KGaA has established itself as a key player in the global spray adhesives market, offering a diverse range of products tailored to various industries such as automotive, electronics, and packaging. The company's innovative solutions are designed to meet the specific bonding requirements of different applications, ensuring strong and durable adhesion across a broad spectrum of substrates and materials. Henkel's presence in multiple sectors reflects its expertise in developing high-performance adhesives that cater to the evolving needs of industries seeking reliable bonding solutions for their products and components.

The growth of the global spray adhesives market can be attributed to the increasing demand from sectors such as construction, automotive, packaging, and furniture, where these adhesives play a crucial role in providing efficient bonding solutions for a wide range of applications. The segmentation of the market based on resin type, substrate, and end-use industry underscores the diverse properties and applications of spray adhesives. Each resin type offers distinct advantages, with epoxy-based adhesives excelling in strong bonding capabilities for demanding applications, while polyurethane adhesives provide flexibility and durability for tough bonding requirements.

By segmenting the market based on substrate, the importance of matching adhesives to specific materials becomes evident, as different substrates such as plastic, metal, and wood have unique characteristics that require tailored bonding solutions. Plastic substrates, known for their low surface energy, demand adhesives with strong bonding capabilities to ensure effective adhesion. Metal substr

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Spray Adhesives Market : https://www.databridgemarketresearch.com/reports/global-spray-adhesives-market/companies

Key Questions Answered by the Global Spray Adhesives Market Report:

- What is the current state of the Spray Adhesives Market, and how has it evolved?

- What are the key drivers behind the growth of the Spray Adhesives Market?

- What challenges and barriers do businesses in the Spray Adhesives Market face?

- How are technological innovations impacting the Spray Adhesives Market?

- What emerging trends and opportunities should businesses be aware of in the Spray Adhesives Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-drilling-waste-management-market

https://www.databridgemarketresearch.com/reports/global-hydrogen-storage-market

https://www.databridgemarketresearch.com/reports/global-polypropylene-packaging-film-market

https://www.databridgemarketresearch.com/reports/europe-topical-use-acne-treatment-market

https://www.databridgemarketresearch.com/reports/north-america-amniotic-products-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 986

✉ Email: [email protected]