Tailored for Success: Bulk Packaging Solutions for Every Industry

In today’s fast-paced commercial landscape, efficiency is key. Businesses across various industries constantly seek ways to streamline operations and reduce costs. One area that often gets overlooked is packaging. Enter bulk—a game changer for companies looking to enhance their logistics while maintaining quality. But what if you could take this a step further? Imagine customizable Bulk Packaging Solutions explicitly tailored for your industry needs. Each sector has unique challenges from food and beverage to pharmaceuticals that require specialized solutions. This blog will explore the significance of adaptable bulk packaging and how it can give your business an edge in today's competitive market.

The Importance of Bulk Packaging in Modern Industries

Bulk packaging plays a crucial role in modern industries. It streamlines the supply chain, allowing businesses to manage their inventory more effectively. By shipping products in larger quantities, companies can reduce shipping costs and minimize the number of trips required for transportation.

Moreover, bulk packaging enhances efficiency during production and distribution processes. When items are packed together, handling tasks like loading and unloading are simplified. This reduces labour time and increases productivity across various operations.

Quality control is another significant aspect of bulk packaging. Packaging materials protect products from damage during transit while keeping them fresh or secure until they reach their final destination. This is especially vital in sectors such as food manufacturing, where safety standards are paramount.

Additionally, bulk packaging supports sustainability efforts by minimizing waste. Businesses can use fewer resources when packing large quantities rather than individual units. This lowers production costs and aligns with growing consumer preferences for environmentally friendly practices.

Bulk packaging provides flexibility to accommodate different product sizes or types without compromising quality or performance. As industries evolve and adapt to changing market demands, the ability to customize bulk solutions becomes increasingly valuable for maintaining a competitive edge.

Key Features of Customizable Bulk

Customizable bulk packaging offer a range of features designed to meet diverse industry needs. One key aspect is versatility. Businesses can tailor their packaging sizes, shapes, and designs to fit the specific requirements of their products. This adaptability ensures that companies maintain efficiency throughout their supply chain.

Another essential feature is branding opportunities. Customizable bulk packaging allows businesses to directly incorporate logos, colours, and messaging into the design. This enhances brand visibility and creates a cohesive identity across different product lines and markets.

Durability plays a crucial role in bulk packaging as well. High-quality materials provide protection against environmental factors during transit and storage, safeguarding products from damage or contamination. Whether it’s moisture resistance or tear strength, these customizable solutions are built to withstand the rigours of transportation.

Cost-effectiveness is another appealing benefit of such packaging options. Companies can reduce waste by optimizing the size and material used for specific products while maximizing space efficiency in shipping containers or warehouse storage.

Ease of handling cannot be overlooked. Many customizable bulk packages have user-friendly designs that simplify workers' loading and unloading processes. This minimizes labour costs while enhancing operational efficiency throughout logistics networks.

Benefits of Tailored Packaging for Different Sectors

Tailored packaging solutions offer immense benefits across various sectors. Each industry has unique needs that standard packaging often fails to address. Customizable options allow businesses to create packaging that meets specific requirements, enhancing functionality and appeal.

For the food industry, tailored bulk packaging ensures product freshness and safety. Materials designed for temperature control can prolong shelf life while maintaining quality, satisfying consumers and helping brands adhere to strict regulations.

In pharmaceuticals, customized bulk packaging is crucial for protecting sensitive products from contamination or degradation. Tailored designs can include tamper-proof seals and labels with essential information, ensuring compliance and consumer trust.

The cosmetics sector also reaps significant advantages. Unique shapes and eye-catching designs attract customers' attention on shelves while reflecting brand identity. When aesthetics align with functionality, it creates a memorable unboxing experience for consumers.

Optimized bulk packaging benefits manufacturing industries by improving supply chain efficiency. Customized dimensions reduce wasted space during transport, saving shipping fees and storage costs while minimizing environmental impact through reduced waste generation.

Materials and Technologies Used in Bulk Packaging

Choosing materials in bulk is crucial for functionality and sustainability. Commonly used materials include cardboard, plastic, metal, and glass. Each material offers advantages specific to various industries. For instance, corrugated cardboard provides excellent protection during transport while remaining lightweight.

Plastic has revolutionized the bulk packaging landscape. It's versatile and can be moulded into various shapes and sizes, making it ideal for multiple products. Innovations like biodegradable plastics are gaining traction as businesses strive to reduce their environmental impact without compromising quality.

Metal containers are often favoured in sectors such as food and beverage due to their durability and ability to preserve freshness. Aluminium cans are lightweight yet sturdy, offering an airtight seal that extends shelf life significantly.

Recent technological advancements have introduced innovative packaging options that enhance user experience. Packages with RFID tags allow companies to track inventory seamlessly while providing customers with real-time information about product origin or expiration dates.

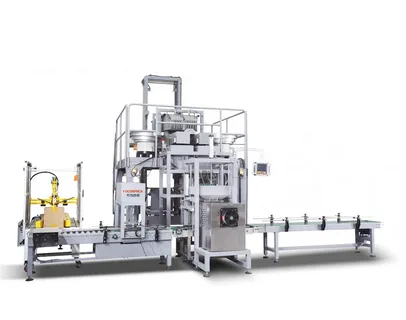

Automation technology also plays a critical role in bulk packaging processes today. Automated filling machines ensure consistency in package size while reducing labour costs—resulting in increased efficiency across production lines tailored specifically for diverse industry needs.

Ensuring Sustainability in Packaging Equipment Suppliers

Sustainability is becoming a critical focus in Packaging Equipment Suppliers. With increasing awareness of environmental issues, industries are seeking ways to minimize their ecological footprint. Sustainable practices benefit the planet and enhance brand reputation among eco-conscious consumers.

One practical approach involves using recyclable and biodegradable materials for packaging. Companies can opt for options like recycled cardboard or compostable plastics, which help reduce landfill waste. These materials often perform just as well as traditional options while supporting a more circular economy.

Customization allows companies to adapt quickly to market demands or seasonal trends without significantly overhauling their supply chains. Being responsive gives brands an edge over competitors while maintaining cost-effectiveness.

Innovative technologies play a vital role in creating sustainable bulk. Advances such as water-based inks and energy-efficient production processes contribute to greener practices without compromising quality. By leveraging these innovations, businesses can meet sustainability goals while maintaining operational efficiency.

Reducing excess packaging is another strategy that organizations are adopting to ensure sustainability. Streamlining package sizes reduces material use and transportation costs and carbon emissions during shipping. This approach benefits both the environment and the bottom line.

Collaboration across supply chains is essential for promoting sustainable solutions. When manufacturers, suppliers, and retailers work together toward common goals, they can drive meaningful change within their industries—creating lasting impact beyond individual companies.

Industry-Specific Packaging Requirements

Different industries require unique packaging require unique packaging to ensure product safety and compliance. For example, the food and beverage sector often requires airtight containers to maintain freshness and prevent contamination. Regulations in this industry demand materials safe for consumption and capable of withstanding temperature fluctuations.

Stringent Standards in Pharmaceuticals Packaging

Pharmaceutical packaging prioritizes protection from external factors while ensuring ease of use for consumers. Child-resistant features and clear labelling are essential, adhering to rigorous safety and usability standards.

Aesthetics and Functionality in Cosmetics Packaging

Cosmetics packaging balances visual appeal with functional design. Protecting delicate formulations from exposure to light or air is crucial, while customizable options enable brands to create standout designs without compromising product quality.

Durable Bulk Packaging for Industrial Products

Industrial goods like chemicals or machinery parts require durable packaging capable of withstanding rough handling during transport and storage. These packages also prevent leaks or spills, ensuring both safety and reliability.

Innovative E-Commerce Packaging Solutions

E-commerce has reshaped packaging strategies, emphasizing lightweight designs for cost-effective shipping while maintaining robust protection for goods. Tailored bulk solutions cater to diverse sectoral demands, ensuring products reach customers safely.

How Customization Enhances Brand Identity and Efficiency

Customization in bulk plays a pivotal role in shaping brand identity. Businesses tailor their packaging to create a unique visual appeal that resonates with consumers. Custom colours, logos, and designs can communicate the brand's essence effectively. This differentiation helps products stand out on crowded shelves.

Moreover, personalized packaging fosters emotional connections between brands and customers. It tells a story—a narrative that reflects values and mission. Consumers are more likely to trust brands that invest in thoughtfully designed packaging, and such engagement builds loyalty over time.

Efficiency is another critical aspect enhanced by customization. Tailored bulk can be optimized for specific product dimensions or distribution needs. This precision minimizes waste and maximizes storage space during transportation, saving both time and resources.

Businesses can also benefit from streamlined operations through customized designs that align with manufacturing processes. The right fit ensures faster packing times and easier handling for workers in warehouses or production lines.

Customization allows companies to adapt quickly to market demands or seasonal trends without significantly overhauling their supply chains. Being responsive gives brands an edge over competitors while maintaining cost-effectiveness.

Conclusion

Customizable Bulk Packaging Solutions are a game changer for businesses across various industries. They offer flexibility and adaptability that standard packaging cannot match. Companies can tailor their packaging to meet specific needs, ensuring products are protected and appealing to consumers. The impact of well-designed bulk packaging extends beyond functionality. It plays a crucial role in brand identity, allowing companies to stand out on the shelves or during transport. A unique design can spark interest and enhance recognition among target audiences. Moreover, as industries become increasingly aware of environmental concerns, sustainable options within customizable bulk packaging have gained traction. Brands that prioritize eco-friendly materials contribute positively to the planet and attract environmentally conscious consumers. Investing in tailored bulk is also an opportunity for businesses to streamline operations. Efficient designs can reduce waste and lower costs associated with shipping and storage.

FAQs

What industries benefit from Bulk Packaging Solutions?

Bulk Packaging Solutions solutions can be used in virtually every industry. From food and beverage to pharmaceuticals, chemicals, and retail products, tailored designs meet specific operational needs while ensuring product safety.

How does customization affect costs?

While initial investments in custom designs may seem higher, they often lead to long-term savings by enhancing efficiency and reducing waste. Customizable options allow companies to use materials more effectively and streamline production processes.

Are there sustainable options for bulk packaging?

Yes! Many manufacturers now offer eco-friendly materials such as biodegradable plastics or recyclable cardboard. Sustainable practices not only appeal to environmentally-conscious consumers but also comply with increasing regulations regarding waste management.

What should businesses consider when choosing a supplier?

Reviewing a supplier's reputation, material quality, customization capabilities, and sustainability practices is essential. Reviewing reviews or case studies can provide insight into how well they have met other clients' needs.

|

Related Business Listings |